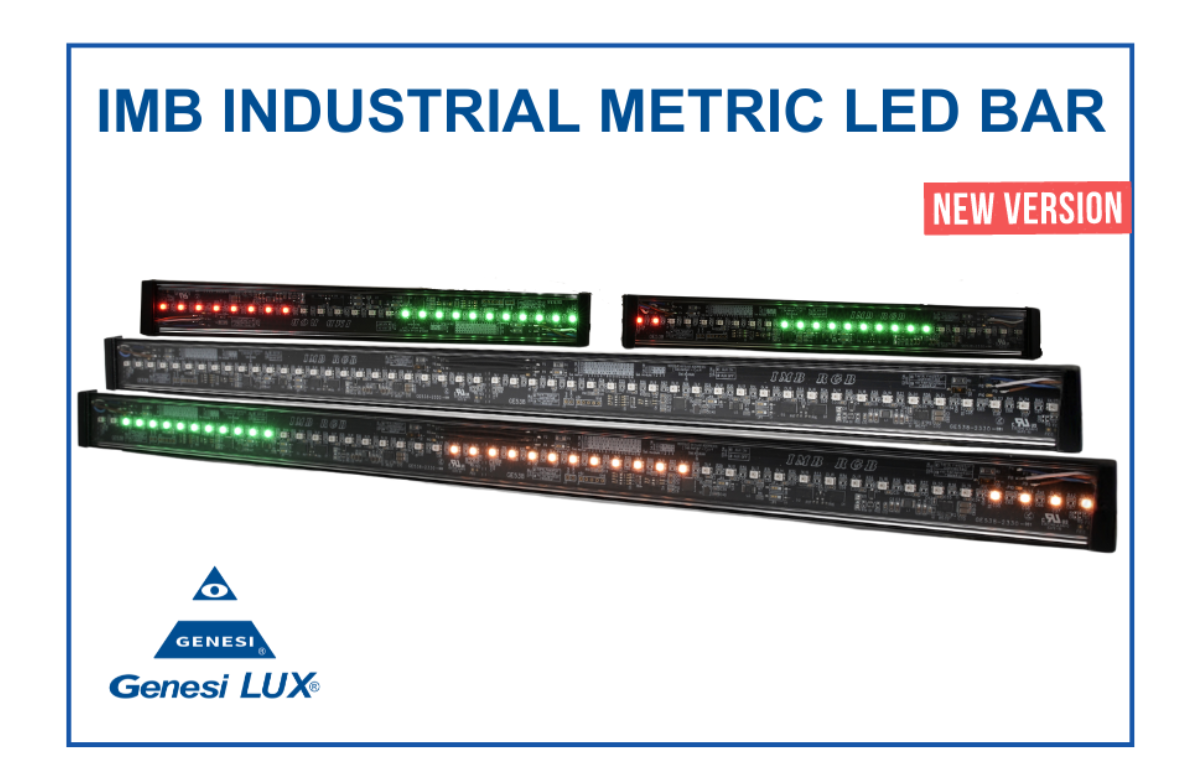

IMB – Industrial metric led bar

The new industrial automation processes, resulting from recent technological developments underlying both improved working conditions and the creation of new business models, may be regarded as the driving force behind the latest innovations in the industrial lighting solutions developed by Genesi Elettronica.

The Industrial Metric Led Bar (IMB) is the perfect representation. Designed to ensure full compatibility with Industry 4.0, this is an efficient interconnection between industrial processes where the use of sensors, optical barriers, displays, laser pointers and sirens are of outmost importance. The aforementioned statement is achieved through the adoption of a LED illuminator, being it a human-machine visual communication system.

The IMB is suitable for several industrial applications, such as:

- Machine loading indicator;

- LED light signal;

- Machine, cobot or industrial plant position indicators;

- Product tracing after machine vision.

The product, developed to meet the company consumer’s demand, can be defined as a simple, flexible and cost-effective solution for machine integration, while meeting the required safety and reliability parameters.

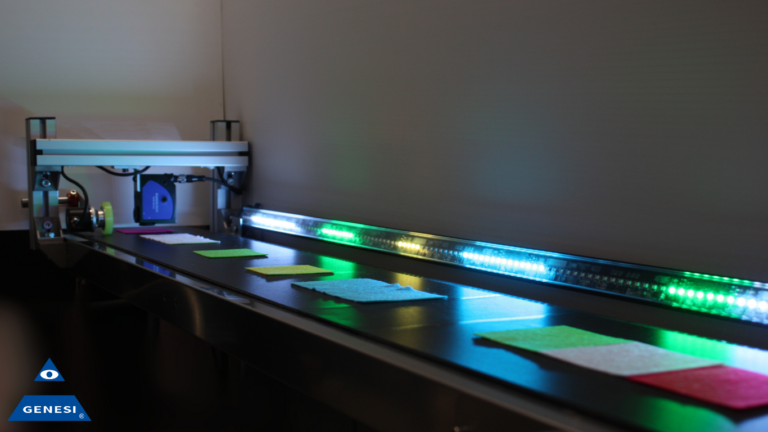

To make the transmission of information from the conveyor to the illuminator effective, the IMB is equipped with a communication system that works in conjunction with a PLC logic unit, which enables serial communication (with RS485 standard).

This information transmission can be performed through the use of different systems, such as linear cameras or sensors.

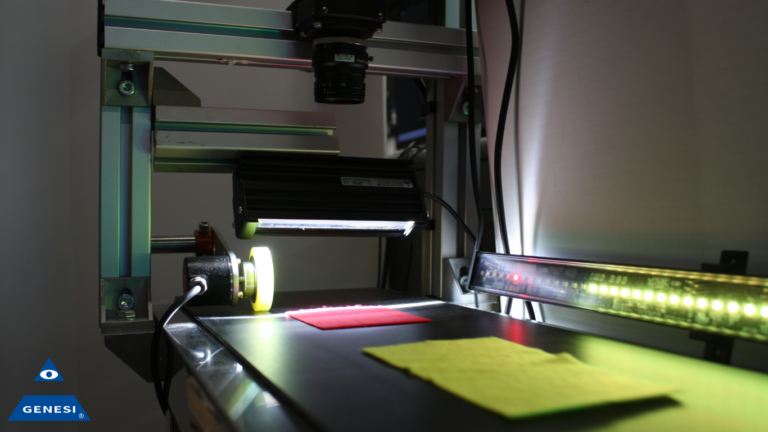

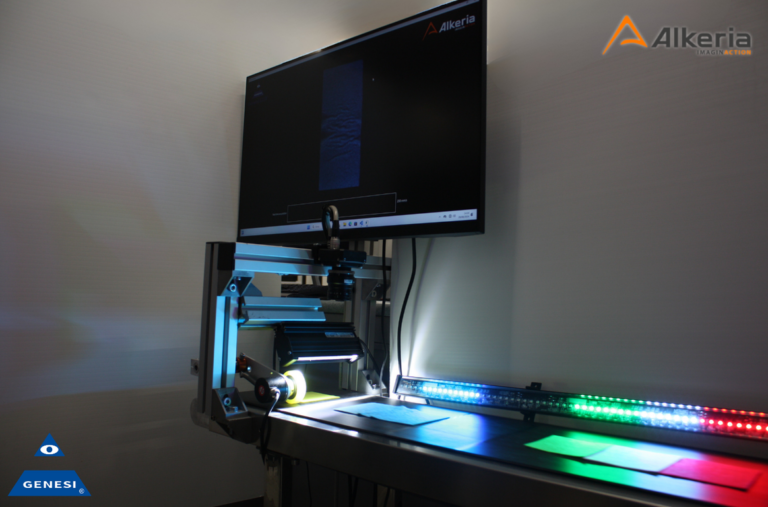

In the former case, namely in the communication system characterised by the combination of a linear camera and a PLC logic unit, the transmission of information to the illuminator is carried out through the use of a software that will have the task of processing the data collected by the camera in the image acquisition process as the objects pass underneath the lens. For the application demonstration, it was decided to use a linear camera supplied by Alkeria, which, together with software also developed by the same company, is capable of detecting the colours in RGB format of the objects as they pass over the conveyor.

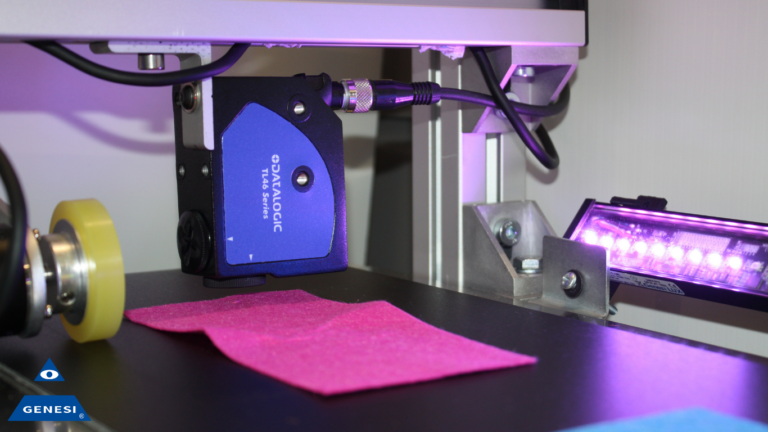

In the latter type of system, on the other hand, the transmission of information is characterised by the presence of a colour presence sensor, supplied by Datalogic, capable of detecting the colour of objects in RGB format.

In both cases, the sensor (encoder) can accurately detect the movement of the conveyor and allows the systems to adapt to different conveyor speeds.

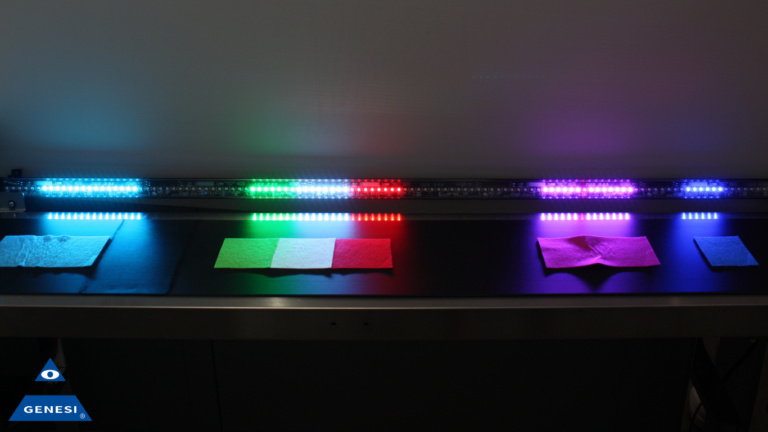

The characteristics of both systems are perfectly suited to the IMB manufactured by Genesi, which, as a result of the combined signal provided, in the first case, by the camera and, in the second case, by the colour sensor, is able to recognise the colour of the object on the tape.

In conclusion, what makes Genesi’s product unique in its field are the hereunder technical specifications:

- RS485 or CANBus native communication standard, with Ethernet, EtherCat, IO-LINK interface accessories;

- RGB LED Colour;

- LED definition from 4mm to 10mm and bar modularity with 25cm LED bar.

- Physical position addressing for each 25cm module up to a length of 16mt with modular parts up to a maximum length of 4mt;

- Driving speed of each individual LED up to 500 changes per second;

- Integrated light output to adapt to ambient lighting conditions;

- Electrical and mechanical safeties designed for industrial environments;

- 24Vdc;

- IP65.