GEVX Ultrapower Linear Light – Model Evolution

GEVX: “HOW A NEW SOLUTION IS BORN”

In the industrial environments occurs more and more often the need of intense and focused light. For that reason, for over 10 years, we have been developing and producing LED solutions for industrial lighting and vision systems.

In 2012 the first Genesi illuminator able to focus the light was born. This is the GEM-L10, which thanks to a special asymmetric secondary lens in polycarbonate reduces the beam angle to 10 °. For this product the tested transmittance is 82% while the focus is obtained to 30 mm.Â

GEM remains to this day one of the most popular products. Indeed, with its 40W per meter it expresses excellent light output that collimates to a factor x 3.5 with white LEDs.

NEW CHALLENGES: the GEVX modelÂ

Nowadays the industrial lighting has to face many challenges:

Need for more and more continuous emission light;Â

Narrower beam angles in order to have further working areas;

Secondary lens optimisation to guarantee the best light efficiency

UV and IR led use with wavelengths up to 1650 nm (InGaAs)

To reduce the mechanical bends above all over 1 mt length, in order to guarantee a greater light stability.

In 2019 these needs led us to develop the GEVX project that meets the industrial requirements with these solutions:

Continuous use light power over 100 W per meter

5° beam angle with focal point at 60-80 mm

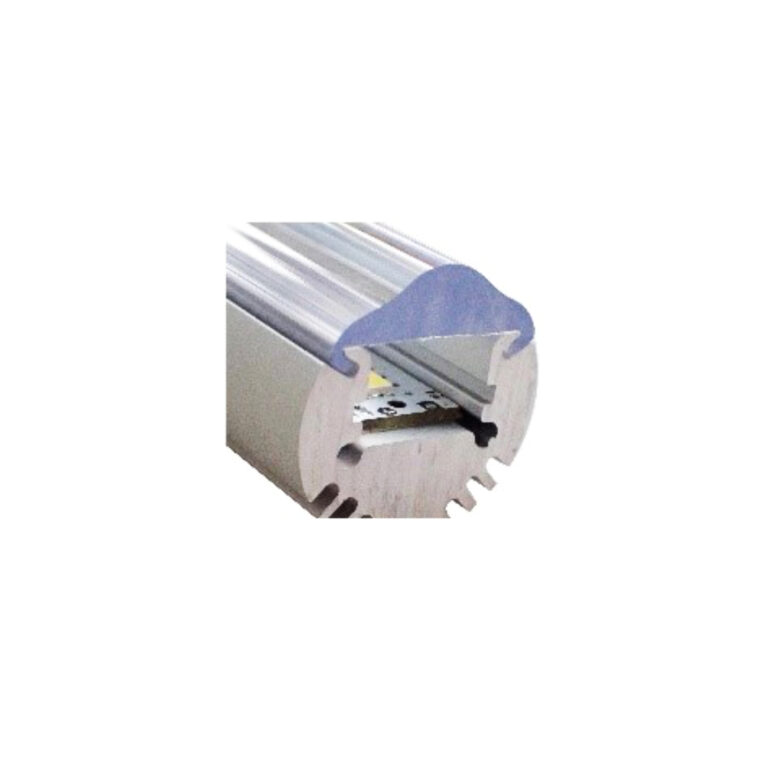

Symmetrical secondary lens with 30 mm diameter and factor multiplied for 5 (on white led)

Secondary lens in PMMA (88% transmittance) usable from 350 nm to 1000 nm or secondary lens in PC polycarbonate (82% transmittance) usable from 1000 to 1650 nm

Mechanical case moulded with bend under 1 mm for 300 cm length

In addition to these important innovations, the project also introduces these new features:

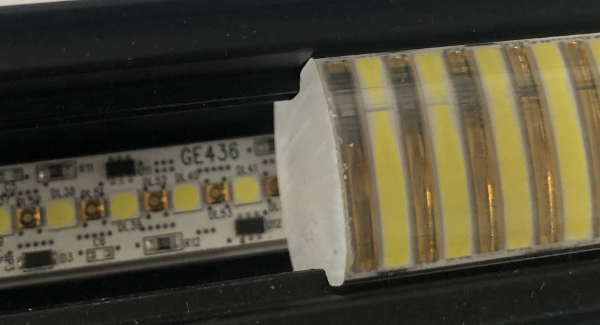

Possibility of multi-frequency solution: circuits with 2 or 3 different types of LEDs (white – red – IR or UV and IR) can be incorporated in a single GEVX illuminator. Where previously 2 or 3 different

illuminators were used, it is now possible to do everything with just one, reducing costs and size;

Optimised fixing points for various needs;

Optional cover to increase the protection degree;

High-perfomance backlight variant.

GEVX ULTRAPOWER LINEAR LIGHT – MODEL EVOLUTION

New models have been introduced in recent months to meet a wide range of needs, the GEVX project lends itself to being customised and adapted to the most various fields of application.

Hereunder the main developments on the new models:

Secondary 20 or 40° lens on single LED in addition to 5° on basic model

Protection degree up to 65, using special PVC adhesives

Ultra-transparent cover permeable to UVA and UVC LEDs

New series of printed circuit boards that allow the simultaneous use of up to 4 LED channels with independent triggers