GB IP69K – lighting solutions for Food & Beverage sector

The Food & Beverage sector is characterised by its ability to combine innovation and technology in its industrial processes. As a matter of fact, in order to meet specific market requirements and different hygiene standards, the adoption of advanced machine vision technologies becomes essential for optimising production processes.

Genesi Elettronica’s GB IP69K is the ideal choice when there is a need to provide uniform and intense lighting. Belonging to the Backlight – Blue Line lighting solutions family, the illuminator is designed to ensure maximum reliability and resistance in humid environments, contact with products of different acidities and high-pressure water jets.

With a 316 stainless steel construction, to ensure its use in food environments where hygiene and ease of cleaning are essential to avoid contamination and comply with safety regulations, the solution is designed to provide strong resistance through the adoption of a polycarbonate cover. This combination results in greater reliability and resistance to external physical and chemical agents, allowing it to be used in all kinds of conditions.

The IP69K rating indicates not only maximum protection against dust, but also its resistance to intensive washing and the use of aggressive detergents. Specifically, this version is identified by the code -X69K, where -X stands for its stainless steel design.

As a product of the Blue Line family, the solution has integrated electronics that allows for temperature control, duty cycle and 4 operating modes, as follows:

- Continuous use

- Semi-continuous use

- Impulsive use

- Analogue regulation

Furthermore, the integrated micro-controller performs temperature and duty cycle controls to prevent possible failure or malfunction of the illuminator.

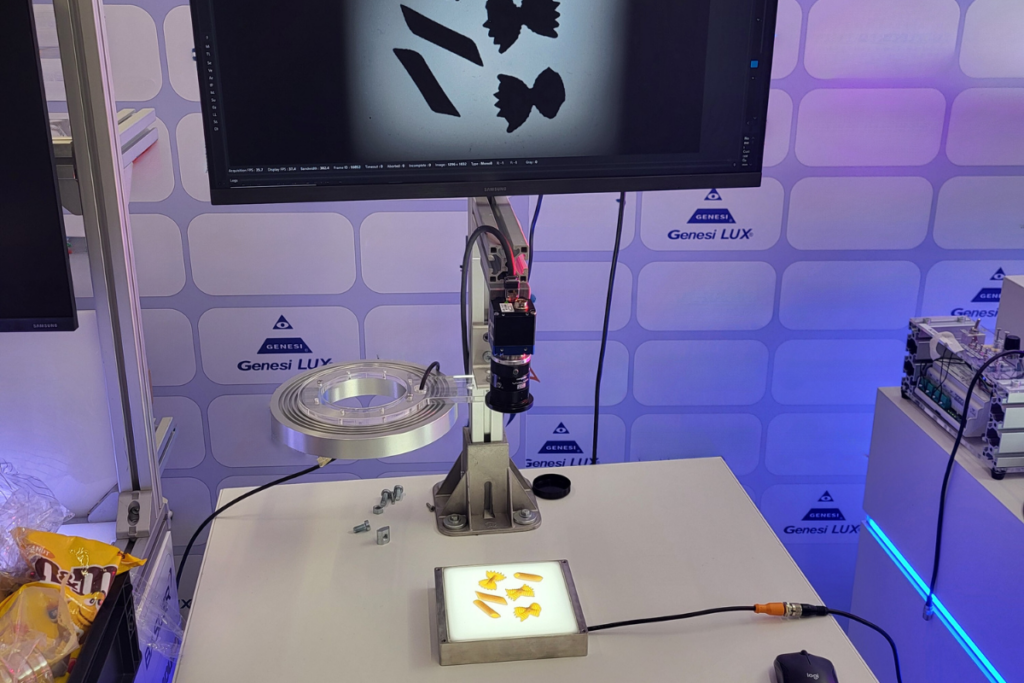

In the application demonstration our GB IP69K, a white light solution in continuous use, is used in combination with a camera and software to acquire a sharp image of the different pasta types on the illuminator. The image can therefore be used by computer vision software to carry out not only the classification of pulp types, as mentioned above, but also dimensional checks or defect detection.